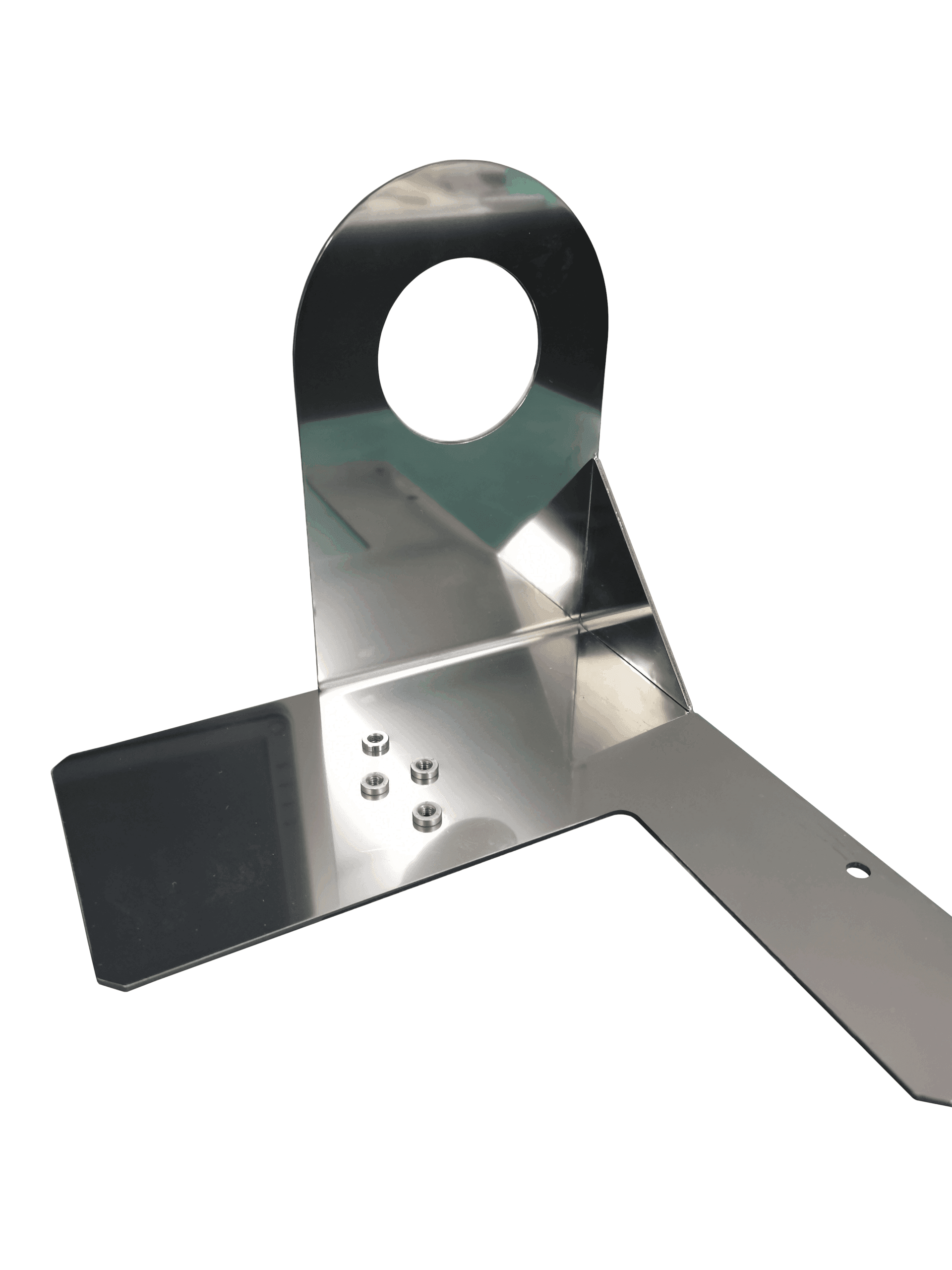

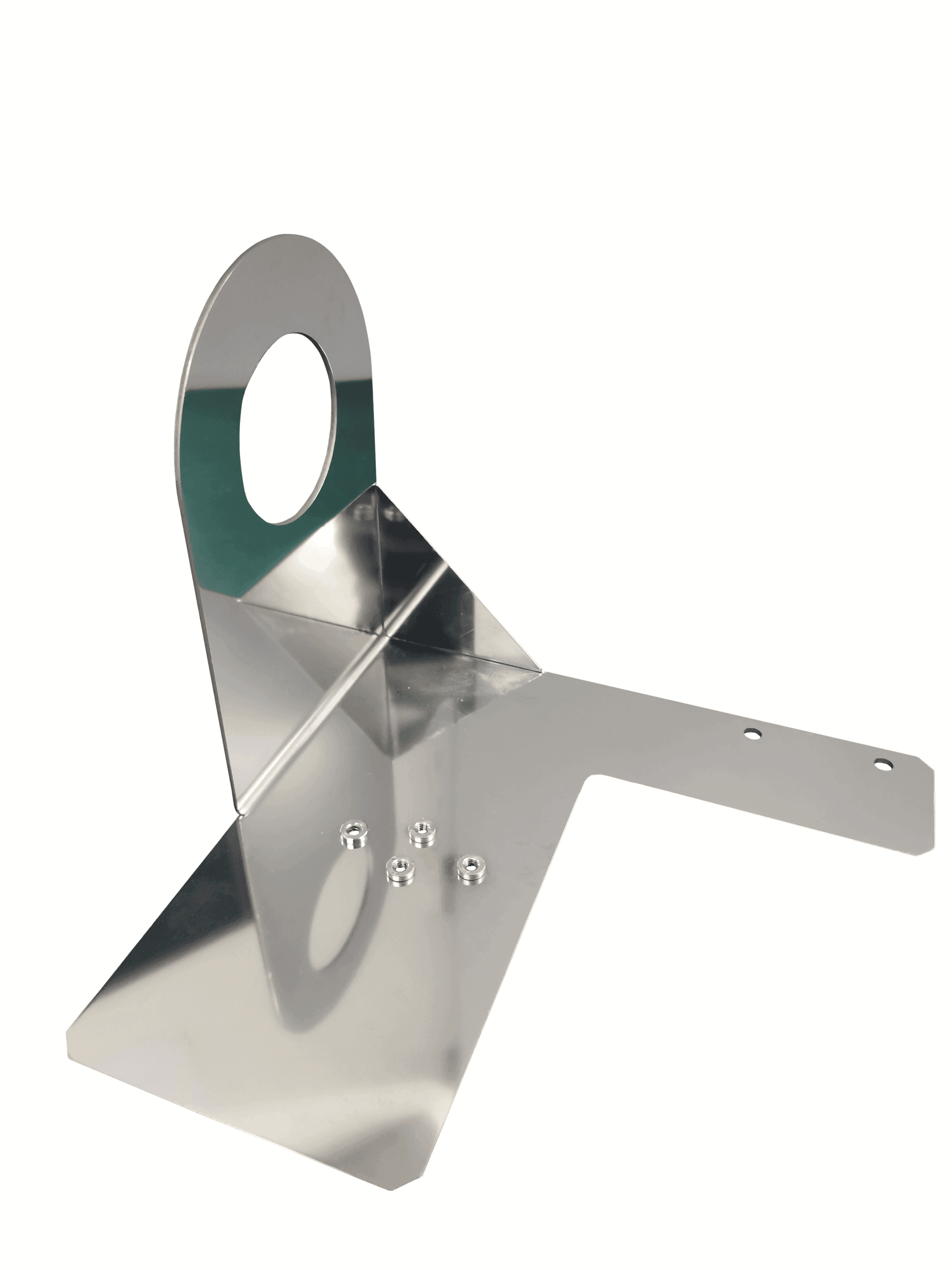

Bracket Cover

The Bracket Cover is a precision-fabricated stainless steel component designed to protect and support mounted parts, shafts, or protruding elements in industrial and equipment assemblies. Featuring a bent sheet metal structure with a circular cut-out and mounting points, this bracket cover provides both structural support and a clean, finished appearance for mechanical installations.

Features:

- Protective Bracket Cover Design: Designed to cover and protect internal components or mounting areas while maintaining accessibility where required.

- Circular Cut-Opening: Integrated round opening allows clearance for shafts, rods, or mounted components passing through the bracket.

- Precision Bent Sheet Metal: Formed with accurate bends to ensure rigidity, proper alignment, and stable installation.

- Pre-Drilled Mounting Holes: Includes mounting holes for secure fastening to frames, panels, or machine structures.

- Reinforced Corner Bend: Bend side flange provides additional strength and stability to the bracket structure.

- Smooth Edge Finish: Clean-cut edges improves safety during handling and installation while enhancing overall appearance.

Material:

- Stainless Steel: Durable, corrosion-resistant, and easy to maintain – suitable for cleanroom, laboratory, machinery, and industrial equipment applications.

Dimensions:

- Length: Customizable

- Width: Customizable

- Height: Customizable

- Mounting Hole Size & Position: Customizable

- Cut-Out Diameter: Customizable based on application requirements

Applications:

This Bracket Cover is commonly used in machinery assemblies, equipment frames, automation systems, enclosures, and mechanical supports where component protection, alignment, or structural reinforcement is required.

Customization:

Customization options include material thickness, overall dimensions, cut-out size, mounting hole configuration, surface finishing (hairline or polished), and additional bends or reinforcements based o application needs.

Got questions or need support? Our team is here to assist you! Feel free to reach out during our business hours, Monday through Friday, from 8:30 AM to 6:15 PM.